<rt id="4ausu"></rt>

<rt id="4ausu"></rt>

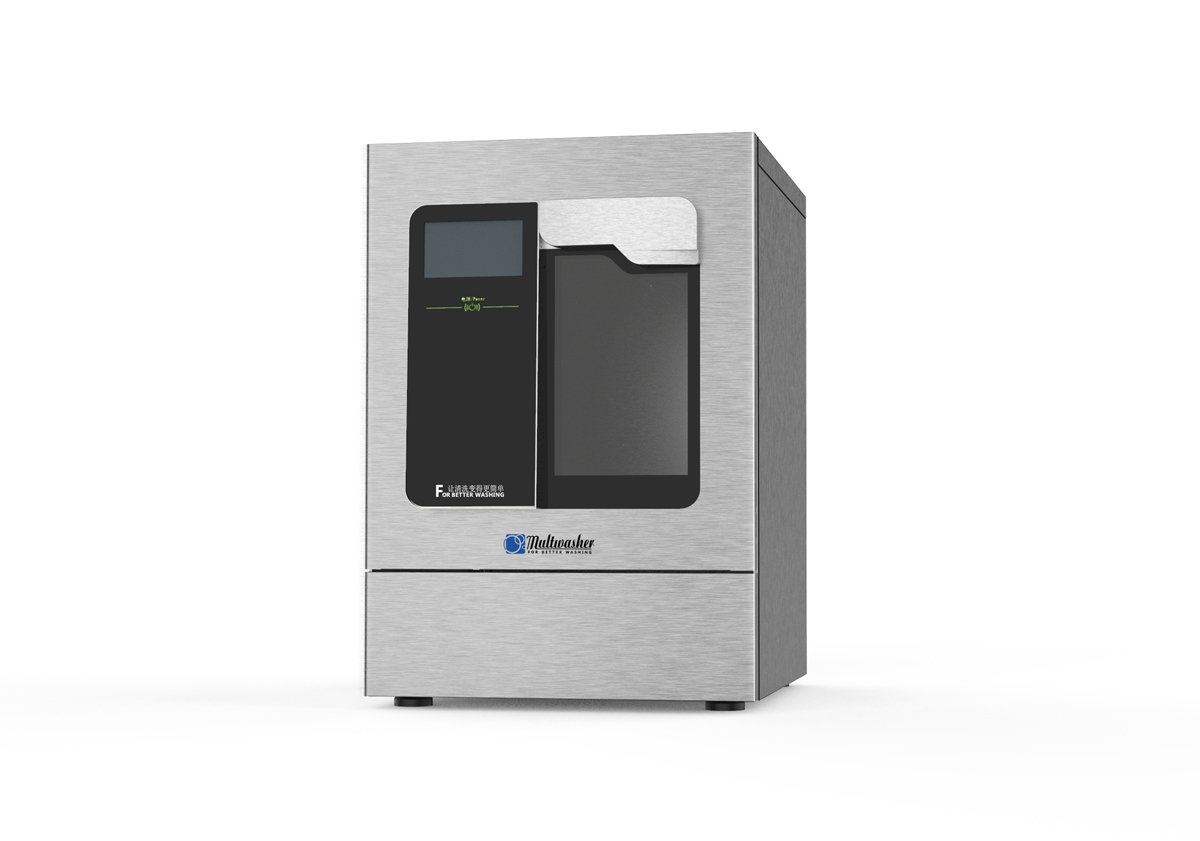

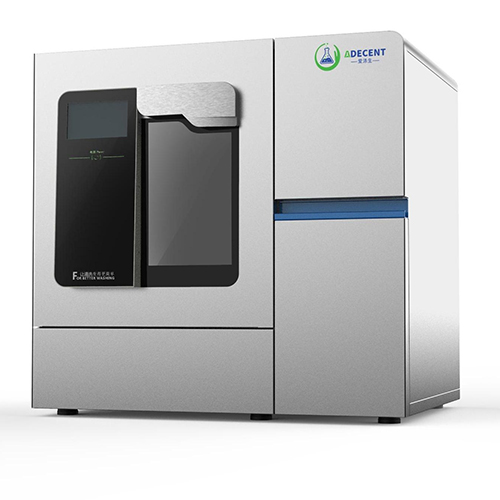

1. Product Overview

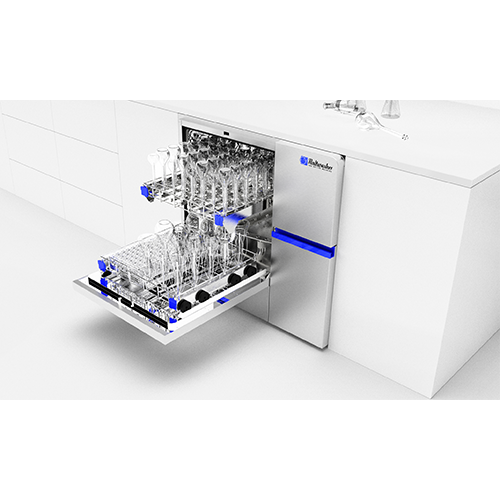

The LW8518 cleaning machine is commonly used for cleaning and disinfecting laboratory utensils made of glass, ceramics, metal, plastic, and other materials. For example: test tube, beaker, volumetric flask, weighing bottle, flat bottom flask, burette, filter funnel, centrifuge tube, reagent bottle, burette, capillary, etc.

2. Working principle

Load the laboratory utensils onto the container loading basket, load them into the inner cavity of the cleaning machine through the slide rail, remove the pollutants (including organic matter, inorganic compound, protein, etc.) on the containers through the cleaning steps, and clean the residues on the containers; Remove pollutants and cleaning agent residues on the utensils through rinsing steps, so that the ion residue on the utensils is lower than the detection limit. Remove cells, viruses, and bacterial residues on the utensils through disinfection steps, reducing the number of live microorganisms to the specified level.

3. Product Application

General laboratories, such as organic, inorganic, physical chemistry, biology, microbiology, medical, pharmaceutical, food or cosmetics industry laboratories.

4. Performance characteristics

4.1 Equipment structure

Adopting an inner hidden fixed structure, the bolt threads have no external leakage, and the bending hidden corners and rounded corners are designed with no sharp edges or weld leakage, showing a beautiful and clean appearance.

4.2 Equipment and Materials

Adopting a 304 grade stainless steel shell and a 316 L grade stainless steel inner cavity, this material is an upgraded material with added elements such as zirconium, molybdenum, and cobalt, which has better corrosion resistance and high-temperature resistance.

4.3 Control System

The use of PCB printed circuit board control and 7-inch display screen greatly reduces the labor intensity of the operator, making the entire cleaning and monitoring process more intuitive and convenient.

4.4. Circulating system

The circulation pump with a capacity of 400 liters per minute provides extremely strong cleaning power, and the circulation pressure sensor ensures the correct operation of the water pump. If an obstacle is detected, the water pump will be turned off before overheating to prevent damage to the cleaning machine.

4.5 Heating system

The total heating power of the heating system is 4KW, ensuring that the cleaning solution is quickly heated to the appropriate cleaning and rinsing temperature.

4.6. Filtering System

The tertiary sewage filtration system utilizes surface, rough, fine, and fine filters to prevent debris from entering the recycling process during cleaning, thereby protecting internal components.

4.7 Distribution System

Liquid cleaning agents and acidic neutralizing agents can be dispensed according to program parameters using a built-in peristaltic pump. The cleaning agent washing pipe is equipped with a liquid level sensor to detect the remaining amount of cleaning agent in the cleaning agent bucket.

5. Product parameters

| Product name: | LW8518 |

| Boundary dimension: | 602 * 650 * 860mm |

| Inner cavity volume: | 180L |

| Number of basket layers: | 2 layers |

| Total load: | 5KW |

QRCODE

QRCODE Contact:Miss hao

Mobile:+8615013202531

Email:277410312@qq.com

Address:7th Floor, Shangsheng Building, Jiahe Wanggang, Baiyun District, Guangzhou City